Versatility

Versatility

Power and Speed

Power and Speed

Working Area

Working Area

Machine Dimensions

Machine Dimensions

Accuracy and Precision

Accuracy and Precision

Versatility

Versatility

Power and Speed

Power and Speed

Working Area

Working Area

Machine Dimensions

Machine Dimensions

Accuracy and Precision

Accuracy and Precision

Yohan Laroudie

Yohan Laroudie

Michael Fichtner

Michael Fichtner

Andi Roth

Andi Roth

Gerardo Arcoraci

Gerardo Arcoraci

Steve Opioka

Steve Opioka

OMTech laser engravers seamlessly integrate with RDWorks, providing an intuitive interface and robust editing tools for precise design adjustments.

With support for LightBurn, users gain access to advanced control features, enabling detailed customization and efficient management of complex engraving tasks.

The compatibility with CorelDRAW allows for smooth import and creation of intricate vector designs, ensuring high-quality results for every project.

No, a CO₂ laser cannot engrave stainless steel without an additional marking solution. Fiber lasers are typically used for direct engraving, as they have the ability to mark stainless steel without the need for coatings or sprays.

Engraving removes material to create a permanent, deep mark on stainless steel, while etching involves using chemicals or laser beams to create a surface-level design. Engraving is more durable, especially for high-wear applications.

No, engravings on stainless steel made with fiber lasers are highly resistant to wear, heat, and corrosion. These marks are permanent and do not fade, ensuring long-lasting durability in demanding environments.

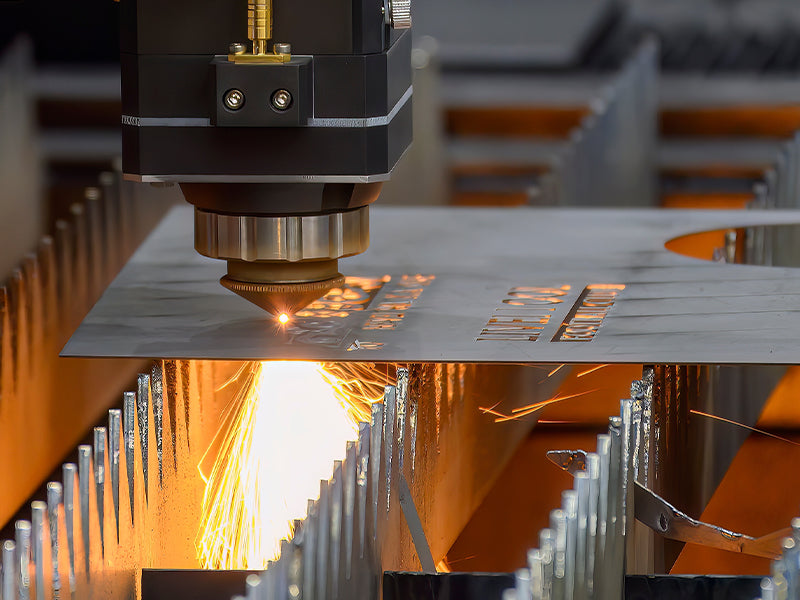

The thickness that can be cut depends on the laser power. High-powered fiber lasers can cut stainless steel up to 5mm or more, while lower-powered lasers are generally used for marking rather than cutting thicker materials.

To clean stainless steel engravings, use a soft cloth with mild soap or alcohol. Avoid abrasive cleaning materials, as they can damage the engraved surface and compromise the engraving's clarity and finish.