Versatility

Versatility

Power and Speed

Power and Speed

Working Area

Working Area

Machine Dimensions

Machine Dimensions

Accuracy and Precision

Accuracy and Precision

Versatility

Versatility

Power and Speed

Power and Speed

Working Area

Working Area

Machine Dimensions

Machine Dimensions

Accuracy and Precision

Accuracy and Precision

Yohan Laroudie

Yohan Laroudie

Michael Fichtner

Michael Fichtner

Andi Roth

Andi Roth

Gerardo Arcoraci

Gerardo Arcoraci

Steve Opioka

Steve Opioka

OMTech laser engravers seamlessly integrate with RDWorks, providing an intuitive interface and robust editing tools for precise design adjustments.

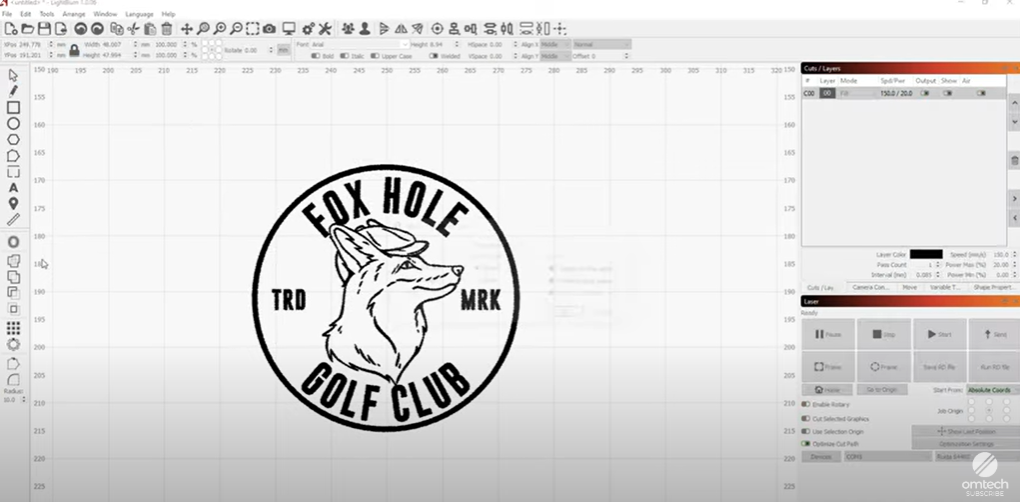

With support for LightBurn, users gain access to advanced control features, enabling detailed customization and efficient management of complex engraving tasks.

The compatibility with CorelDRAW allows for smooth import and creation of intricate vector designs, ensuring high-quality results for every project.

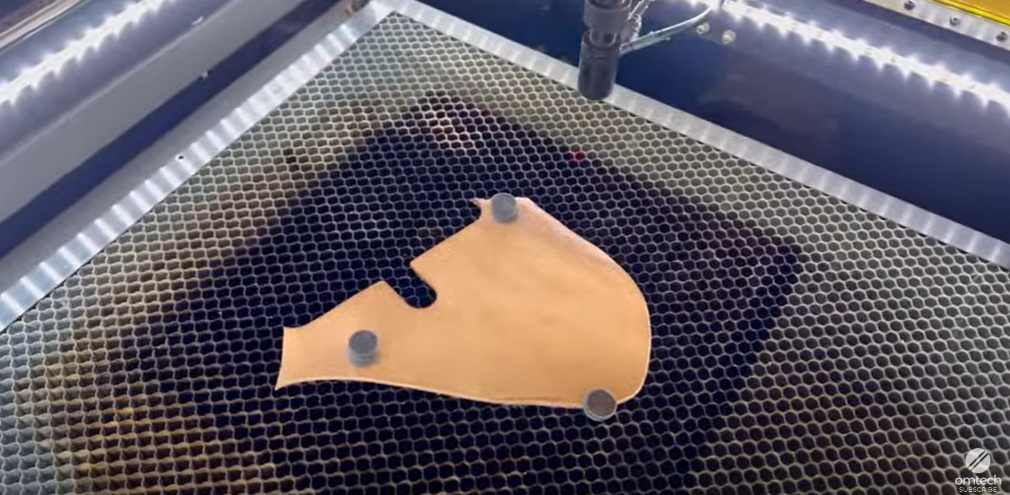

Laser engravers work with a variety of leathers, including genuine leather, faux leather, and vegetable-tanned leather. The settings must be adjusted according to the thickness and type of leather to achieve the best results without damaging the material.

Maintaining a laser engraver when working with leather involves cleaning the lens regularly, checking the exhaust system for debris, and ensuring the ventilation system is working effectively to handle leather fumes and residues produced during engraving or cutting.

Yes, it is possible to engrave both sides of leather. However, for optimal clarity and aesthetics, engraving on the front side is preferred, as it is easier to see and the design tends to look cleaner and more refined.

The time required for cutting or engraving leather depends on factors like design complexity, leather thickness, and power settings. Simple cuts can take only seconds, while more detailed engravings may take several minutes to complete.

Yes, laser engravers can cut thick leather (up to 6mm or more) with higher power settings. For thicker leather, multiple passes may be needed for clean cuts, and settings should be adjusted to prevent burning or excessive fraying of edges.