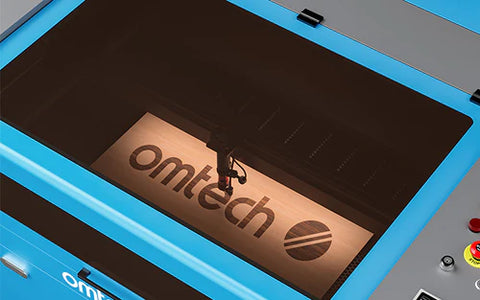

CO2 lasers use a gas mixture to create the laser beam, most of which is carbon dioxide. They are excellent for engraving non-metallic materials such as wood, plastic, and acrylic. CO2 lasers also offer a high-quality cutting and enable detailed engravings. They are widely used in fields, including sign making, arts and crafts, and industrial manufacturing.

CO2 Laser vs Fiber Laser vs MOPA Laser: Choose the Best Laser Engraving Machine

Laser engraving and cutting machines are widely used and available nowadays. Choosing the right machine is crucial for businesses and hobbyists looking for precise and efficient engraving work. However, given the multitude of options available on the market, the decision can be overwhelming. In this ultimate guide, we will help you understand the difference between CO2, fiber, and MOPA laser machines. All three types of laser engravers have different characteristics, advantages, and disadvantages, suited for various purposes of use.

What is the difference between CO2, fiber, and MOPA lasers?

The main differences between CO2, fiber, and MOPA lasers lie in how they work and the types of materials they can engrave.

Fiber lasers use a fiber light source, specifically designed for processing metal materials such as stainless steel, aluminium, and copper. They offer high precision and fast engraving speeds. Fiber lasers are widely used in the metalworking industries, particularly for applications such as metal marking, engraving, and cutting.

MOPA lasers (Master Oscillator Power Amplifier) are special types of fiber laser that offer more precise control over pulse frequency, pulse width, and the power of the laser beams. They enable flexible and precise engraving control, especially on delicate materials or in applications with specific laser parameter requirements. The capability of MOPA lasers to create color markings on stainless steel has attracted a lot of attention. MOPA lasers are used in areas, including jewelry manufacturing, electronics industries, and medical technology industries.

What is a CO2 laser engraving machine and how does it work?

CO2 laser engraving machines are all-in-one engraving and cutting machines with CO2 laser technology. CO2 lasers use gas as its working material. The main working material consists of gases like carbon dioxide, helium, and nitrogen, with carbon dioxide making up the highest proportion. This is why it's called a CO2 laser. CO2 lasers can be activated by electricity and operate in the far-infrared spectrum at a wavelength of approximately 10,600 nm. The CO2 laser was originally invented by laser physicist Kumar Patel in 1964 at Bell Laboratories. It was the first carbon dioxide laser and remains one of the most widely used type of lasers on the market today. The CO2 laser engraving machines can engrave or cut a variety of materials, including acrylic, wood, paper, leather, plastic, and many more.

A CO2 laser engraving machine uses a CO2 laser source to generate an infrared beam. The beam is then directed through a series of mirrors and focused by a lens. The focused beam is then aimed at the surface of the material, which is securely positioned on a table or platform. The laser beam then produces intense heat upon contact with the material, making its surface to vaporize or melt and thus forming precise cutting or engraving in a specific pattern.

What is a fiber laser engraving machine and how does it work?

A fiber laser is a form of solid-state laser that employs an optical fiber as its active medium. Within a fiber laser, a doped fiber optic core, encased by a cladding acting as an optical guide, serves as the gain medium. When the doped fiber core is energized by light from an external source, it generates and amplifies the laser signal within the optical fiber, resulting in high power and energy output.

A fiber laser works by using an optical fiber as a resonator in which the laser light is generated. The fiber consists of a doped core surrounded by a layer of non-doped material. When injecting pump light into the fiber, absorption occurs within the doped core, leading to a population inversion. This inversion in the lasing medium prompts oscillation between mirrors situated at both ends of the fiber, ultimately resulting in the emission of laser light.

The laser light is emitted through the resonator's exit mirror and can be used for engraving or cutting materials. By using an optical fiber as a resonator, a fiber laser can maintain high beam quality and efficiency, making it ideal for many industrial applications.

What is a MOPA laser engraving machine and how does it work?

A MOPA laser is a type of solid-state laser commonly used in many industrial applications, including material processing, marking, lettering, and engraving. MOPA stands for "Master Oscillator Power Amplifier", indicating that the laser consists of both a "master oscillator" and a "power amplifier". In contrast to other solid-state lasers, MOPA allows improved control over laser pulse properties, such as pulse width and pulse frequency.

The primary laser source in the MOPA fiber lasers is the fiber laser itself. The laser beam is initially generated in the main laser oscillator. Then, the generated laser beam is amplified or modulated through an optical power amplifier. This amplified laser power is then directed to the oscillating lens in the MOPA laser marker, allowing for precise control over the laser beam's path for high-speed engraving applications.

What are the advantages and disadvantages of CO2, fiber, and MOPA laser engraving machines compared to each other?

CO2, fiber, and MOPA laser engraving machines are different types of laser engraving machines suitable for different applications and materials. Here are some advantages and disadvantages of each machine compared to each other:

CO2 Laser Engraving Machines

Advantages:

- Suitable for engraving and cutting materials, including wood, acrylic, leather, paper, fabric, plastic and metal coating

- High precision and engraving quality at low power

- Low price compared to fiber and MOPA laser engraving machines

Disadvantages:

- Not suitable for engraving uncoated metal

- Limited lifespan of the laser source

- Requiring large space

Fiber Laser Engraving Machines

Advantages:

- Suitable for engraving metals and plastic

- Fast engraving speed and high quality

- Long lifespan of the laser source

- Compactness

- Low maintenance

Disadvantages:

- More expensive compared to CO2 laser engraving machines

- Not suitable for engraving on most non-metallic materials such as wood, paper and, acrylic

MOPA Laser Engraving Machines

Advantages:

- Suitable for engraving metals and plastic

- Flexibility in setting pulse duration and frequency for different engraving needs Gravuranforderungen

- Enables colorful designs on stainless steel and high contrast markings on anodized aluminium

- Fast engraving speed and high quality

- Long lifespan of the laser source

- Compactness

- Low maintenance

Disadvantages

- High purchase cost

- Not suitable for engraving on most non-metallic materials such as wood, paper, and acrylic

Which laser to choose: CO2 laser, fiber laser or MOPA laser?

Choosing the right laser engraving machine requires careful consideration of materials, size of materials, available space, budget, etc. How to Choose a Right Laser Engraving Machine can help you narrow down your options and find the right machine for your needs.

Conclusion

CO2, fiber and MOPA lasers differ from each other in several aspects. CO2 lasers are suitable for processing non-metallic materials, while fiber lasers are specialized for metals. MOPA lasers offer more precise control over the laser beam and are suitable for demanding applications. When choosing the right laser, it is important to consider the specific requirements and materials. CO2, fiber and MOPA lasers each offer unique properties and are widely used in different industries. By selecting the optimal laser for the respective application, precise and efficient engraving results can be achieved.

Related Articles