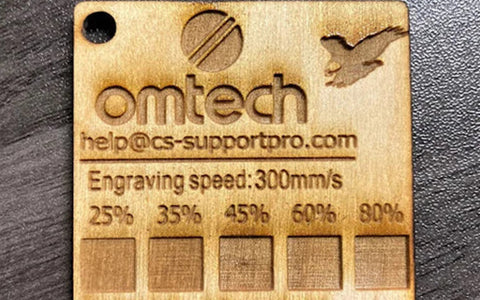

The test of cutting wood, acrylic of different thickness with different speed.

You should know: the importance of testing speed and power before using a laser engraver

The laser engraving and cutting machine is a powerful tool that allows for precise engravings on a variety of materials. However, before using it, the importance of testing the speed and power cannot be ignored. This article will present the concepts of speed and power in laser engraving, as well as how to test and configure these parameters on different materials to achieve the best results. Additionally, this article will help familiarize you with technical terms and updated information, giving you more confidence when using a laser engraver and cutter.

The importance of speed and power in laser engraving and cutting

Speed and power are two key factors that affect the results of engraving. Speed refers to the laser's travel speed over the material's surface, while power represents the intensity of the laser. Properly setting the speed and power ensures the depth, clarity, and efficiency of the engraving and cutting. Setting the speed and power too high or too low can result in a shallow engraving, blurry results, or even burning the material. Therefore, testing the speed and power before the actual engraving is crucial.

What is speed and power in laser engraving?

Speed in laser engraving refers to the speed at which the laser moves across the surface of the material and the cutting speed of the material. It is usually expressed in millimeters per second or inches per second. The higher the speed, the greater the distance the laser travels in a given time, which reduces processing time.

However, simply setting the machine to the maximum speed does not always guarantee good engraving results. For example, if the speed is too high, it may skip key parts of the image or the cutting depth may be insufficient. On the other hand, if the speed is reduced too much, the laser may stay in one place for too long, which can burn the workpiece.

The power in laser engraving represents the intensity of the laser and is typically expressed in watts (W). The higher the power, the greater the energy of the laser and the deeper and more visible the engraving will be.

The power and speed of the laser are not related, but finding the perfect balance between the two is crucial for obtaining the best results. A laser with higher power can achieve deeper and darker cuts. Additionally, thicker materials require more power than thinner ones. However, if the power is too high, it can burn the workpiece and generate unwanted smoke.

The wood and acrylic cutting test, with different thicknesses, using different speed and power settings at 80% of 130W.

How to test speed and power on different materials?

Before performing laser engraving, it is recommended to test the speed and power on the selected material to determine the optimal setting. Here are some steps to conduct these tests:

- Select suitable test material: Choose a similar scrap material to the one you will use in your actual project. This will allow you to better understand how the laser works on that specific material.

- Prepare the test design: Select a test design with different line thicknesses and curves. This will enable you to evaluate the engraving results with different speed and power configurations.

- Set initial parameters: Establish the initial speed and power parameters according to the specifications of your laser engraving machine and the characteristics of the material.

- Conduct the tests: Perform the tests using the initial parameters and observe the engraving results. Pay attention to the depth, clarity, and possible burning on the material.

- Adjust the parameters: Make adjustments based on the test results. If the engraving is too shallow, you can increase the power or reduce the speed; if the engraving is too deep, you can decrease the power or increase the speed.

Setting the speed and power

When configuring the speed and power, it is important to consider the characteristics of the material, the desired engraving depth and clarity, among other factors. Here are some recommendations:

Different materials require different speed and power calibrations in laser engraving. Even if you are using different types of the same material, their characteristics can be significantly different and affect the final product's results. For example, plywood and MDF are common wood materials. Engraving fine patterns (curved edges, complex shapes, etc.) on plywood can be more challenging due to edge fragmentation and possible gaps in the visible layer edges, requiring a reduction in power. On the other hand, MDF has a more uniform consistency, resulting in smooth cutting edges without gaps or splinters, allowing for the use of higher power.

If the results of your laser engraving tests are not satisfactory, take the time to adjust the speed and power levels and perform new tests. Pay special attention to the cutting edges. A smooth edge indicates a correct configuration, while a rough or jagged edge indicates the need to increase the power or reduce the speed.

Conclusion:

Before using a laser engraving machine, it is crucial to test the speed and power to achieve the best engraving results. Through testing on different materials and adjusting the speed and power, you can find the optimal configuration to achieve the desired depth, clarity, and engraving efficiency. Remember that testing and adjustment are an ongoing process, and with accumulated experience, you will be able to skillfully set the speed and power of the laser engraving machine, creating impressive works.

Please note that this article aims to provide general guidance and tips. In practice, refer to the user manual of your laser engraving machine and make adjustments and tests according to your specific situation.

Related Articles