Surface Preparation Process before Laser Engraving on Materials

Laser engraving technology has been widely used in modern manufacturing industry. It allows for high-precision and efficient engravings and markings on materials such as metals, plastics, and wood, among others. However, to achieve optimal engraving results, it is crucial to carry out an appropriate surface preparation process. In this article, we will explore surface preparation techniques for laser engraving on different materials.

Why is surface preparation important?

When using laser engraving, the laser beam interacts with the material's surface. If the material's surface has impurities, grease, dust, or other contaminants, they can interfere with the energy transfer of the laser beam and affect the quality of the engraving. Moreover, some material surfaces may reflect the laser beam, resulting in poor engraving quality. Therefore, through proper surface preparation, it is ensured that the laser precisely impacts the material, thus achieving the desired engraving results. Next, we will address the key aspects of surface preparation for different engraving materials.

Surface preparation for metals in laser engraving:

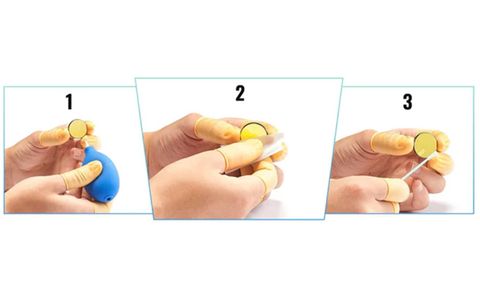

- Cleaning: Cleaning is the first crucial step in the surface preparation process. Metal surfaces may contain grease, oxides, or corrosion, which can affect the transmission of the laser beam and the quality of the engraving. Therefore, before carrying out laser engraving, the metal surface should be cleaned with a suitable cleaning agent and a soft cloth to ensure that it is free from dust and dirt.

- Deoxidation: For special metals such as stainless steel, an acid solution can be used to remove oxides and improve the quality of the engraving.

- Application of auxiliary products: While a fiber laser engraving machine is generally used for metals, if you have a CO2 laser engraving machine and are interested in engraving on metal surfaces, it is recommended to use auxiliary engraving solutions that can help achieve good results in metal engraving.

Surface preparation for wood in laser engraving:

- Surface Smoothing: An important step in the preparation of wooden surfaces is sanding. Using sandpaper or sanding wheels, the surface of the wood should be smoothed to make it even and without irregularities. If the wood surface is uneven, the laser engraving machine may have difficulty maintaining a constant focal distance, which will result in uneven or blurry engraving.

- Application of Coatings: For some special woods, such as hardwood, paint or varnish can be applied to improve the hardness and wear resistance of the wood, as well as the quality and durability of the engraving.

Surface preparation for plastics in laser engraving:

Choosing the appropriate type of plastic is crucial for achieving good results in laser engraving. Some plastics, such as acrylic and polycarbonate, react very well to laser energy and can produce clear engravings. Furthermore, transparent or light-colored plastics can provide greater contrast and clarity in the engraving. However, other types of plastic, such as polyethylene and polypropylene...

In addition to the common materials mentioned earlier, there are also some special materials whose surface treatment requires special attention. For instance, the surface treatment of ceramic materials can use methods like sandblasting or chemical etching to increase their surface roughness and laser absorption properties. The surface treatment of glass materials can utilize special glass etching agents to achieve etching effects through etching coatings or engraving. Surface treatment methods for these special materials should be selected and tested on a case-by-case basis.

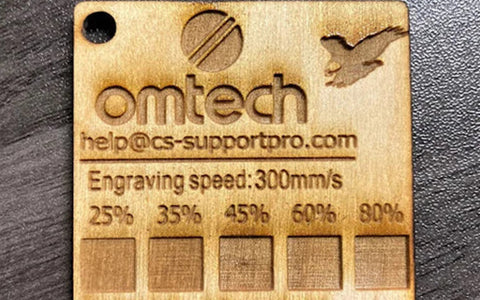

When selecting materials and surface treatment techniques, it is recommended to perform various sample tests to determine the optimal engraving parameters and treatments. Furthermore, the requirements for material and surface treatment may vary between laser equipment and engraving machines, so it is advised to consult the recommendations and guidelines of the equipment manufacturer.

Conclusion

In summary, the preparation of the surface of the material to be engraved by the laser engraver is a fundamental step to ensure the quality and effectiveness of the engraving. By properly treating the surface, impurities can be removed, reflections can be reduced, and the delivery of the laser beam can be improved to achieve the desired engraving effect. Choosing the right material and adopting the appropriate surface treatment techniques will help you achieve high-quality laser engraving work.

Related Articles