Your Business. Your Machine. Empowered by OMTech.

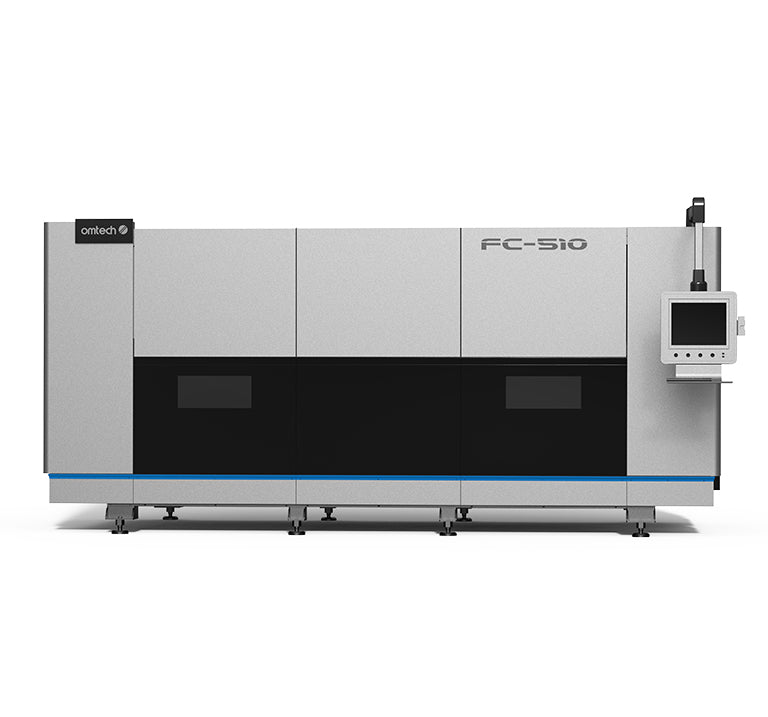

FC-510 Fiber Laser Cutting Machine

FC-105 Fiber Laser Cutting Machine

FC-44 Fiber Laser Cutting Machine

FC-105SA Fiber Laser Cutting Machine

Fiber lasers are optimized for cutting metals like stainless steel, aluminum, brass, and copper with high efficiency and speed. They use a solid-state laser source with a fiber optic delivery system. CO2 lasers, on the other hand, are gas-based systems ideal for cutting and engraving non-metal materials such as wood, acrylic, leather, and fabric. If you’re working with metals, a fiber laser like OMTech’s FC Series is the better choice.

Laser power depends on the material type, thickness, and production volume.

For thin sheet metals (up to 3mm), 1.5–2kW is often sufficient.

For medium thickness (4–10mm), 3–4kW provides faster cutting and smoother results.

For thicker metals (up to 20mm or more), 6kW is ideal for industrial throughput and precision.

Our team can help you select the best configuration based on your specific use case.

Absolutely. OMTech offers fully tailored machine footprints, including custom bed dimensions, pass-through access, dual shuttle tables, and automatic loading/unloading systems. We’ll work with you to engineer a layout that fits your space, workflow, and expansion plans.

OMTech FC fiber laser machines can cleanly and accurately cut a variety of metals, including:

Stainless Steel

Mild and Carbon Steel

Galvanized Steel

Aluminum

Brass and Copper

Titanium and Alloys

Note: For raw aluminum and reflective materials, we recommend higher power (3kW+) with anti-reflective protection.

Every custom FC solution includes:

Your selected laser power source (1.5kW–6kW)

Fiber laser cutting head with auto-focus

Bed size & frame per your requirements

Chiller system, CNC controller, and exhaust ports

Setup support, user manual, and lifetime U.S.-based technical assistance

Additional upgrades include fume extractors, rotary attachments, and gas handling systems.

Pricing varies depending on power level, size, and add-ons. Entry-level systems (1.5kW, smaller beds) start in the low $2000, while larger industrial systems (4kW–6kW, automated tables) can range from $4000 to $80,00+. We offer flexible quotes tailored to your business needs.

While OMTech FC machines are designed with user-friendly controls, we recommend professional training for first-time fiber laser users. We offer:

Onboarding support and machine setup

Software guidance (CAD/CAM + controller integration)

Maintenance and safety training

Our support team is also available by phone or email for ongoing technical assistance.