What are a honeycomb cutting table and an aluminum slat cutting table in a CO2 laser engraving machine?

In the world of laser engraving and cutting technology, choosing the right work surface plays a critical role in the quality of the final product. With CO2 laser engraving machines, two special types of cutting tables are particularly noteworthy: the honeycomb cutting table and the aluminum slat cutting table. These two types of tables offer unique advantages that make them important elements in the engraving process.

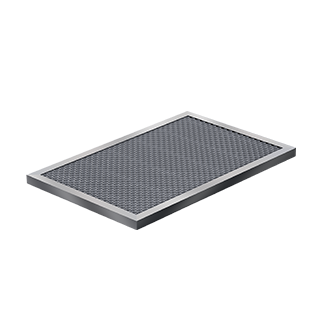

What is a honeycomb cutting table in a CO2 laser cutter?

The term 'honeycomb' describes the structure of the worktable of a laser engraving machine on which the material to be processed is placed. Such a honeycomb bed consists of numerous small hexagonal cells that resemble the pattern of a honeycomb. In the field of laser engraving, it is often referred to as 'honeycomb table,' 'honeycomb worktop,' 'honeycomb pattern,' or 'honeycomb support.' One can also use the internationally recognized English term 'honeycomb.'

The honeycomb cutting support is ideal for applications where freedom from reflection and optimal flatness are crucial – such as when precisely cutting paper and films.

What are the advantages of the honeycomb cutting table?

Material Support: Provides even support for materials of various shapes and sizes, ideal for medium to smaller objects.

Stability: The risk of material deformation is minimized, as stable support is provided. This creates the foundation for precise cutting and engraving.

Reduction of Laser Reflections: During cutting, the laser can hit the support and be reflected back, which can damage the backside of the material. A honeycomb cutting table reduces this risk, as the laser falls into the cells and is absorbed instead of being reflected.

Effective Smoke and Heat Dissipation: Laser cutting or engraving burns the material and generates smoke. The hexagonal cells promote air circulation, improve smoke and heat dissipation, reduce the risk of burn marks on the underside of the material, and prevent contamination of the material by smoke, leading to better engraving and cutting results.

For which materials or applications is the honeycomb cutting support suitable?

- For applications where a reflection-free surface and optimal flatness are crucial, the honeycomb cutting support is ideal for processing a variety of materials – from light to medium-weight paper, cardboard, thin wood, acrylic, fabrics, to plastics.

- The processing of small parts, such as those found in model-making, benefits from the fine honeycomb structure of the table, as it effectively prevents parts from falling through the gaps between the honeycombs.

- Applications that require high precision, since the honeycomb structure provides good support to the material and minimizes deformations.

- Tasks where efficient smoke extraction is important, as the honeycomb structure improves air circulation.

What is an aluminum slat cutting table in a CO2 laser cutter?

An aluminum slat cutting table in a CO2 laser cutter is a type of worktable that consists of a series of parallel aluminum slats. These slats are arranged to form a flat surface on which materials can be placed for cutting or engraving.

What are the advantages of the cutting table with aluminum slats?

Reflection Reduction: Aluminum reflects the laser beam less strongly than other metals, which reduces the risk of reflections that could damage the laser head.

Heat Dissipation: Aluminum is a good conductor of heat. The slat structure allows for efficient dissipation of heat from the workpiece, which reduces the thermal load on the material and prevents deformation. The underside of the cut material is less likely to show burn marks.

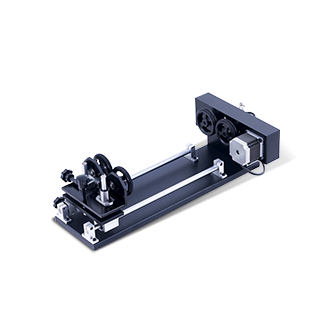

Modular Slats for Flexible Adjustment: The slats can be flexibly removed and inserted. This modular design allows for a customized adjustment of the work table surface to the size and shape of different materials. For irregularly shaped workpieces, special projects, or sensitive materials, the user can reduce the contact surface by removing slats to minimize scratches or damage to the workpiece.

Waste Management: The gaps between the slats allow waste and small parts to fall through the table, keeping the work surface clean and reducing the risk of damage to the workpiece by residues.

Versatility: An aluminum slat cutting table is suitable for a variety of materials and applications, from fine paper engravings to cutting thicker materials like wood or acrylic.

Durability: Aluminum is corrosion-resistant and durable, which means that the cutting table has a long lifespan even with intensive use.

Easy Maintenance: The design of the table allows for easy cleaning and maintenance, as chips and dust are easy to remove.

Improved Cut Quality: By reducing vibrations and providing an even support surface, an aluminum slat cutting table can contribute to improved cut quality.

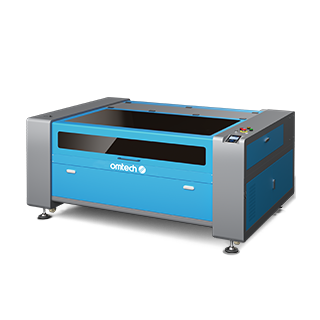

The Polar laser engraving machine offered by OMTech has a honeycomb table:

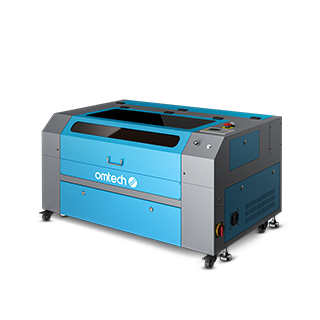

The laser engraving machines of the Turbo and Max series offered for sale by OMTech are equipped with two worktables, namely a honeycomb cutting table and an aluminum slat cutting table.

In addition to the commonly used honeycomb table overlays and aluminum slat cutting tables, there are other types of worktables available, such as the aluminum grid table, the acrylic grid cutting table, the vacuum table, and the ferromagnetic engraving table from Trotec Laser. Each type of worktable has its own characteristics.

Armed with this knowledge, you can now make an informed decision about which type of cutting table is best suited for your applications. Whether it's delicate artworks or sturdy industrial components – an optimized cutting process begins with the right foundation.

Related Articles