How to engrave wood: a beginner's guide

One tool that is on every woodworker's wish list is a laser engraver. Both functional and memorable items can be crafted with these powerful and precise devices.

Laser engravers cut through thick materials with ease by burning the surface of the material, allowing for a wider range of small project options than the typical craft or vinyl cutter. While CNC routers are good for large projects, their attention to small details is incomparable to the accuracy of a laser beam.

If you want to learn how to engrave wood to grow your online business or start a new hobby, investing in a laser engraver gives you endless opportunities to express your creativity and impress your customers.

Don't know where to start? Check out our comprehensive guide to wood applications to expand your knowledge of wood types, project ideas and buying factors.

How does a CO2 laser engraving machine work?

A CO2 laser engraver works by passing electricity through a gas-filled tube (a mixture of carbon dioxide, nitrogen, hydrogen and helium) with mirrors at both ends. This creates a powerful beam of light (laser beam) inside the laser tube, which is reflected by three mirrors onto a focal lens that focuses the laser beam onto your target material.

The laser beam produces a strong infrared light that is invisible to the human eye. First, its long wavelength easily cuts, engraves and marks wood, fabric, paper, glass and leather without touching the surface. Then the excess heat from the laser vaporizes the cut material, leaving a smooth, precise surface.

Advantages of a CO2 laser engraving machine

Here are some reasons why industrial manufacturers, contract printers and DIY enthusiasts rely on CO2 laser engravers:

Non-Contact – The laser beam makes no physical contact with the target material, leaving minimal damage to the integrity of the material and machine.

Affordable – Engravers are low-maintenance machines with inexpensive replacement parts.

Safety - No sharp blades to adjust and the laser beam is sealed in a light box.

Consistent Accuracy - Achieve clean cuts with a smooth finish every time.

Versatility - Engrave on a variety of materials including wood, leather, glass, acrylic and metal.

The best woods for laser engraving

Wood is one of the best media for laser engraving. It looks natural and classic and is perfect for a variety of projects. However, the type of wood used and its imperfections can significantly affect the final product. In order to understand how to engrave wood, it is important to know the different types of wood.

For high-quality, professional engraving, choose a lightweight wood with minimal banding. Lighter wood creates a clearer contrast. The resin content of the wood determines the color tone of the engraving (light to dark). A high resin content results in a darker burn, while a low resin content results in a lighter burn.

The following types of wood are recommended for best laser engraving results:

Alder

Balsa wood

Birch

Cherry

MDF

Plywood

poplar

Wood engraving ideas

1. Personalized Memorabilia

Well-cared for photos create lasting memories that friends and families love to share. Offer your customers a custom engraved image that can be passed down through generations.

Personalization doesn't stop with photos. Other laser engraving project ideas include unique milestone memorabilia, engraved wood signs, custom Christmas ornaments, home decor, accessories and more.

2. Deposits

Effortlessly create intricate inlays by combining the power of cutting and engraving to build cabinets, furniture, chopping boards, musical instruments, bowls and more.

3. Prototyping

Use scrap wood to create intricate patterns for prototypes. Before the development of laser engravers, this work was time consuming and prohibitively expensive. Now you can use a laser system to realize your creativity and sales goals.

How to buy the best laser engraving machine for wood?

Purchasing a wood engraving machine is a smart investment that can pay off. High-power lasers combined with advanced technology enable detailed designs to be engraved on a variety of surfaces.

Please consider these 5 factors before purchasing a wood laser engraving machine:

1. Budget

Budget is the main factor when buying your machine. While purchasing the most expensive machine is unnecessary for most projects, a larger upfront investment can save you power and energy in the long run.

Laser engravers vary greatly in price. View properties such as engraving area, laser power, laser type and the type of material(s) you want to engrave.

We understand that running a business can be expensive. Investing in a laser engraving machine can add unlimited product possibilities without breaking the bank. Also, laser engravers are less expensive than CNC and most woodworking machines.

2. Materials

Let's say you're thinking about purchasing a laser engraving machine to improve your hobby or expand your online business. You probably already have an idea of the materials you want to engrave.

While most laser engravers can engrave multiple types of wood, it is necessary to check the specs. If you plan to expand your engraving options soon, you should choose a device that can also process acrylic, metal and paper.

3. Performance

Purchasing a quality-assured machine can save you setup time and additional material costs. Look for a machine assembled by competent technicians, high spindle performance and precise screw drive. To get the most out of your investment, it is important that the laser engraver is built from quality parts and offers the latest features.

4. Maintenance

Would you rather maintain your laser engraver yourself or hire a professional? The frequency and difficulty of maintenance may vary from device to device.

Purchasing a machine that is difficult to maintain can result in unexpected costs and significant downtime if you have to wait for a technician.

5. Replacement parts

Regardless of how well you maintain your machine, it will eventually require replacement parts. Are the parts easy to source and install, or do you have to wait weeks for a backordered part?

If waiting for replacement parts is affecting your customer service and order times, choose a laser engraver that uses universal, easy-to-order replacement parts.

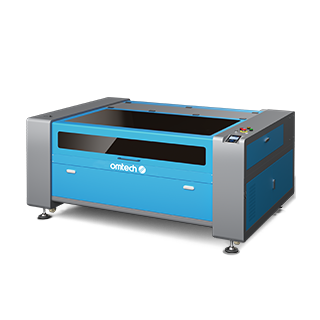

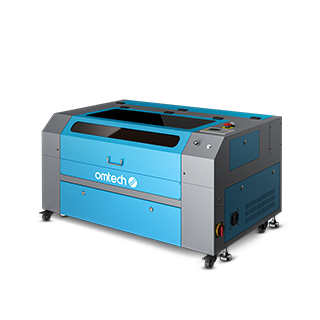

Buy the best laser engraving machine for wood

We hope that after reading this article you have gained a better understanding of wood engraving. If you are looking for a well-built, high-performance laser engraving machine, OMTech offers industry-leading laser engraving machines, software and accessories. We offer professional products for using a laser engraver for small business, hobbies and crafts. Take a look at our laser engraving machine options and feel free to contact our customer service team with any questions.

Related Articles